Professional manufacturer with the design, development and production of rubber and plastic machinery

Share to

New Type Rubber Batch off Cooler Machine for Tyre Tread Film Cooling Production Line

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

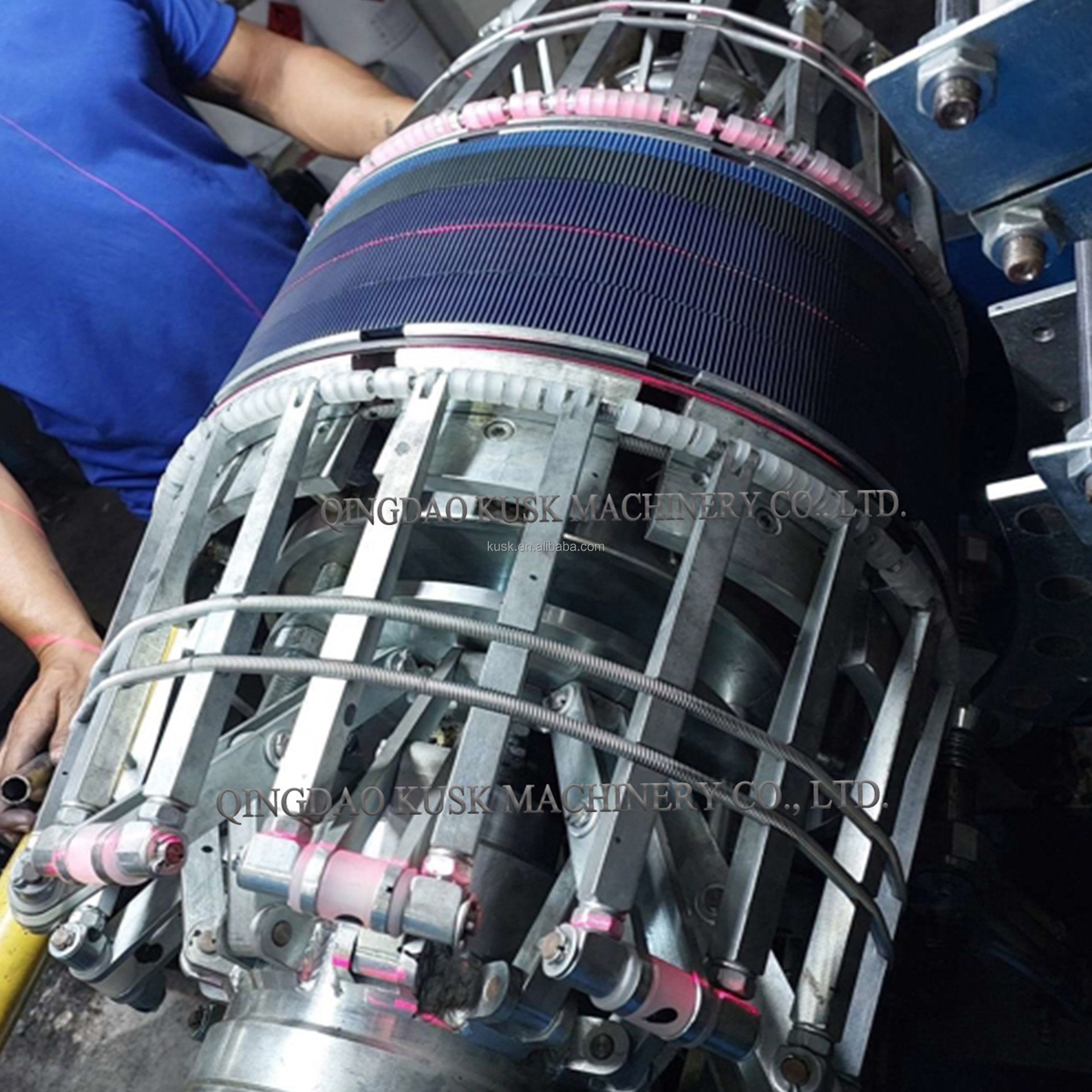

motorbike tyre tread extrusion cooling line

Model

TTC

Line speed

5 ~ 25m/min

Take-up height

900mm

Width of production roller

650mm

(design according to tread width)

Pick-up temperature

≤ 40℃ (Ambient temperature + 5℃)

Cutter: Max. thickness of tread cutting

20mm

Max. cutting width

450mm

Cutting angle adjustment

35° ± 5°

Length tolerance of the cutting component

± 3

Cutting frequency

10 ~ 15 cuts/min

Pressure of compressed air

0.6 ~ 0.8 Mpa

Total motor power

23.3KW

Cooling water consumption

50 ~ 60 m3/h

Dimension (L*W*H)

28000*2000*2800mm

Weight

20000kg

...

..

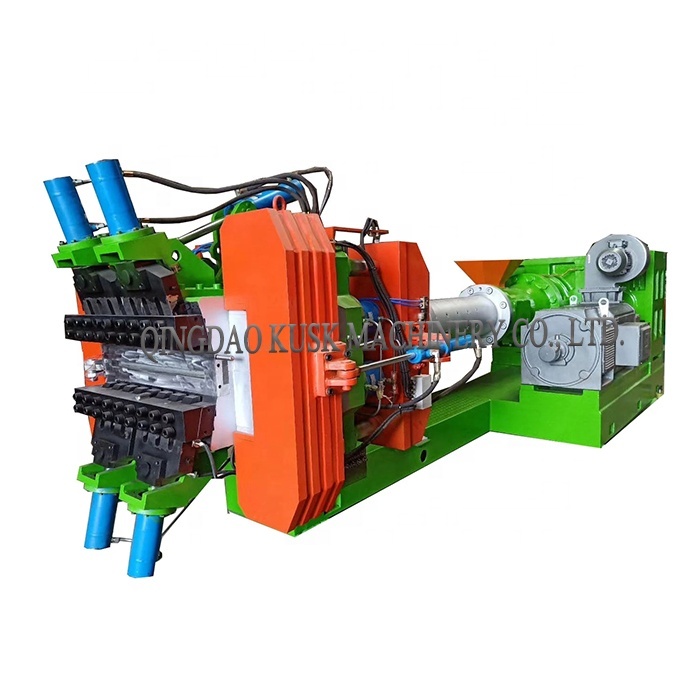

..The Rubber Calender Machine Production Line is a core equipment system in the rubber processing industry, designed to efficiently and precisely process rubber materials into various semi-finished products with uniform thickness and smooth surface.

At the heart of the Rubber Calender Machine Production Line lies the rubber calender machine itself, which is equipped with high-precision rolls made of wear-resistant alloy steel. These rolls can be adjusted to different temperatures and speeds according to the specific requirements of rubber materials, ensuring that the rubber is fully plasticized and pressed into the desired shape. In addition to the calender machine, the production line also includes auxiliary equipment such as rubber mixing machines, feeding conveyors, cooling systems, and winding machines. The rubber mixing machine first processes raw rubber and various additives into a homogeneous rubber compound, which is then transported to the calender machine via the feeding conveyor. After being calendered, the rubber semi-finished product is cooled by the cooling system to maintain its shape, and finally wound into rolls by the winding machine for subsequent processing.

One of the key advantages of the Rubber Calender Machine Production Line is its high production efficiency. With advanced automatic control technology, the entire production process can be operated with minimal manual intervention, reducing labor costs and improving production stability. The line also features excellent precision, as the digital control system can monitor and adjust parameters such as roll temperature, pressure, and speed in real time, ensuring that each batch of products meets strict quality standards. Moreover, the production line is highly flexible and can be customized to produce different types and specifications of rubber products by changing the roll configuration and adjusting process parameters.

The Rubber Calender Machine Production Line finds wide application in various fields of the rubber industry. In the tire manufacturing industry, it is used to produce tire carcass layers, belt layers, and sidewall rubber, which are essential components for ensuring tire performance and durability. In the production of rubber sheets, the line can produce sheets of different thicknesses and widths, which are widely used in construction, automotive, and electrical industries. Additionally, the line is also used in the production of conveyor belts, rubber hoses, and other rubber products, providing reliable processing support for the development of the rubber industry.

New Type Rubber Batch off Cooler Machine for Tyre Tread Film Cooling Production Line

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products