Professional manufacturer with the design, development and production of rubber and plastic machinery

Share to

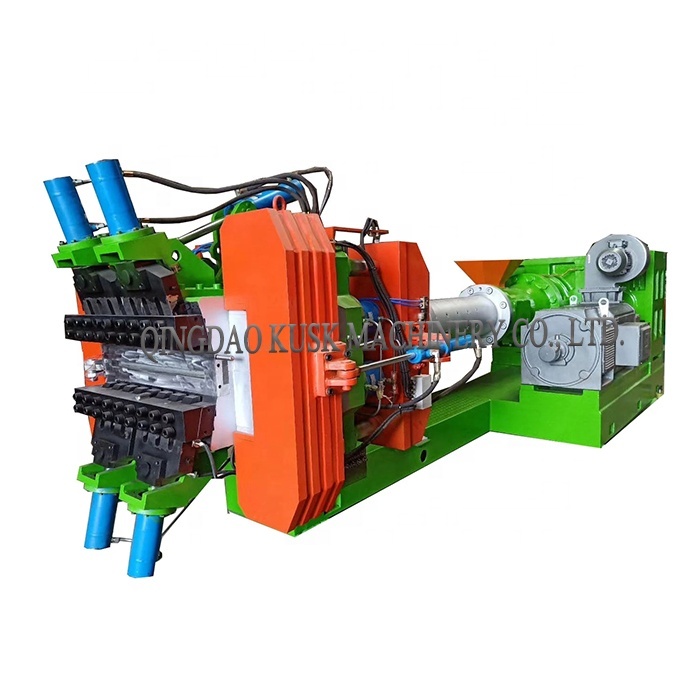

Tyre Retreading Machine Cost Tire Polishing Machine Retreading Tyre Buffing Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

Tire Retreading Process Flow

Tire Casings Collection→Initial Inspection→Old Tread Buffing→Section Repair & Skiving→Cementing & Filling →Cushion Gum→Building Tread Rubber→Ventilating Cloth→Enveloping System→Rims Mounting System→Test Envelope & Inner Tube→Curing Chamber System→Demounting Curing Rims→Undress Envelope→Final Inspection & Test →Finishing Paint→Retreaded Tire in Storage

Product Description

1. Collection of Casings

Worn tyres are collected to select suitable casings for tyre retread.

2. Initial Inspection

Each tyre received in a retread plant is subjected to a rigorous visual inspection. Inspectors are assisted by the use of non-destructive sophisticated KUSK inspection machine.

3. Buffing After inspection

The tyre's old tread is mechanically removed on high speed buffers. KUSK's buffers are extremely accurate and will remove the proper amount of old rubber while turning the tyre to an exact specified diameter and radius.

4. Section Repairs & Skiving

With advances in state-of-the-art repair materials and repair methods, many of these tyres can be routinely repaired and in most cases can be retreaded when the original tread is worn off. The repair station is where any surface injury is treated using effective material and tools for grinding and patching.

5. Cementing and Filling

Even in small injuries it is critical that the injury is cleaned and filled. If this is not done, severe rust, separation and steel cable looseness could take tyre out of service. The injury should be inspected, and then cleaned out with a carbide cutter. After cementing the injury, a vulcanizing rubber stem should be applied to "fill" the injury. This would create a permanent repair that maximizes tyre life.

With KUSK designed-and-built spray booth, your cementing operation can be executed in a clean, efficient & environmentally responsible manner.

6. Building - Tread Rubber

In the pre-cure system, the tread rubber has already been vulcanized with the new tread pattern design. The buffed tyre needs a thin layer of cushion gum to be wrapped around its crown area. The pre-cured tread rubber is then applied with the building machine. This is called the building process.

7.a) Enveloping & Rim Mounting

The built tyres are then mounted with envelops and rims to prepare them for curing.

b) or Double Envelope System

For enveloping, tyres are first fitted an outer envelope at the envelope-mounting table before the inner envelope is fitted into them. The enveloped tyres are then vacuumed out for preparation prior to curing. Modern plants have their casings hoisted by monorail systems. With professional planning from KUSK engineers, you can be assured of workstations designed to maximize output and ease workflow.

8. Curing by Chamber

The tyre is then placed in a curing chamber and the pre-cured tread becomes adhered to the tyre through a vulcanizing process.

Our wide engineering capabilities and experience enable KUSK to build chambers to suit our clients' different preferences for size, steam heated, electric heated, or double heating system, semi-automatic and automatic chambers.

9. Final Inspection & Painting

The retreaded tyre is subjected to a final inspection. This inspection insures that only tyres that meet industry quality standards are allowed to leave the retread plant. All retreaded tyres are encouraged to be returned with the sidewalls painted using a light coat of black tyre paint.

Configuration of Tire Retreading Production Line

1.Curing ChamberName

Size(Diameter*length)

Quantity of tire

DN1500*1500

4 tires

DN1500*2000

6 tires

DN1500*3000

8 tires

DN1500*3500

10 tires

DN1500*4000

12 tires

DN1500*5000

16 tires

Function

The tyre is then placed in a curing chamber and the pre-cured tread becomes adhered to the tyre through a vulcanizing process.

Power

30kw-90kw

Heating Method

Electrical heating, thermal oil heating, steam heating

......

Tyre Retreading Machine Cost Tire Polishing Machine Retreading Tyre Buffing Machine

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products