Professional manufacturer with the design, development and production of rubber and plastic machinery

Share to

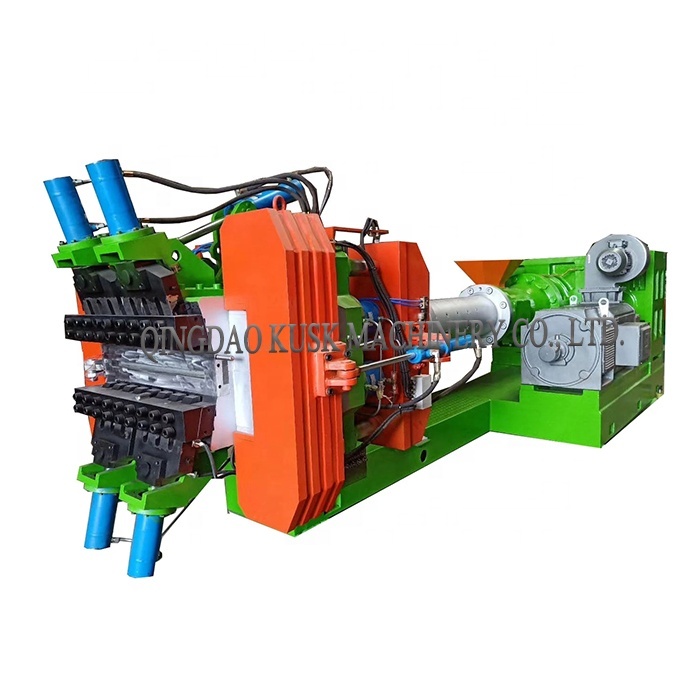

Frame Type Rubber Belt Production Line Making Machine/V Belt Production Line

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

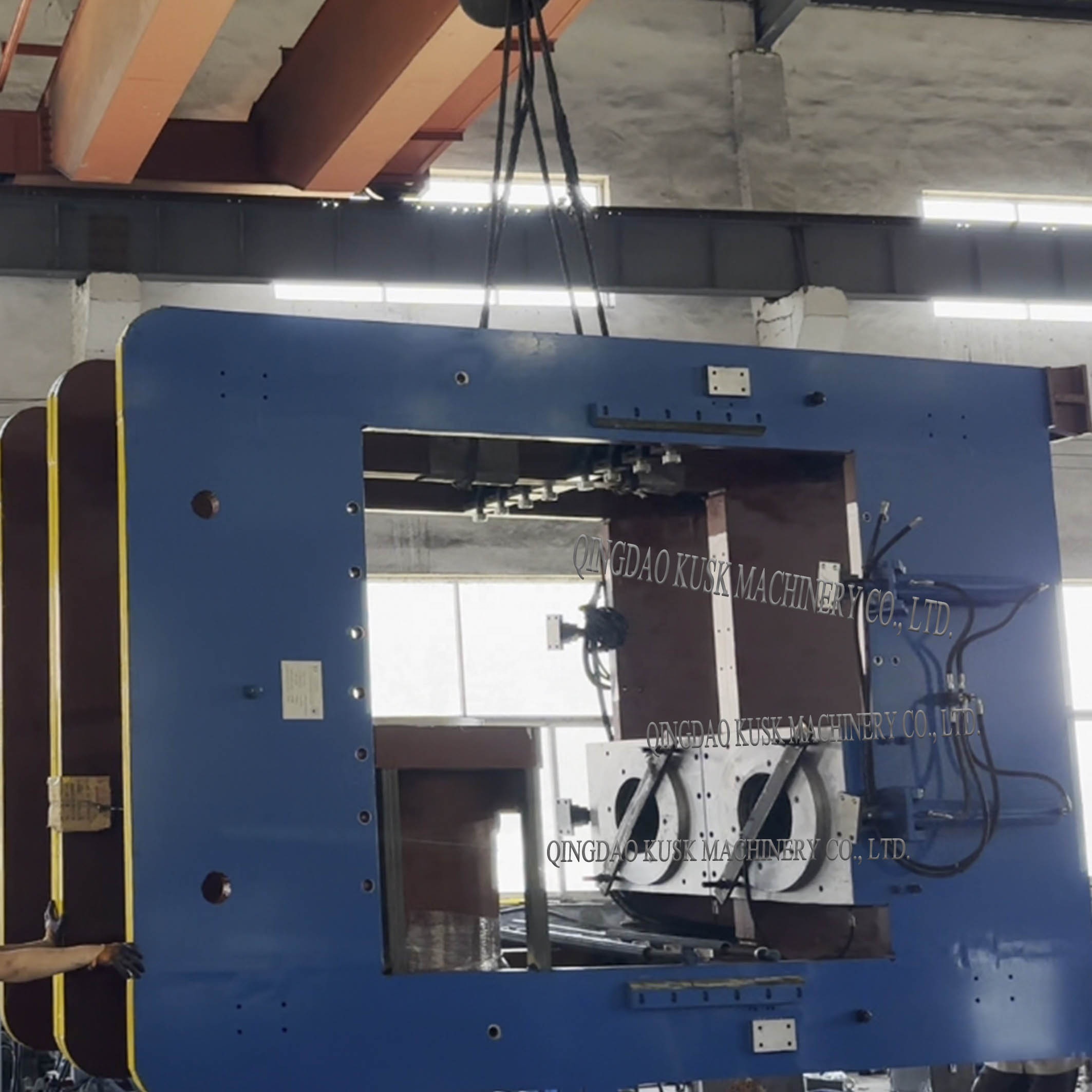

rubber product vulcanizer large frame structure heating press machine with manual push and pull device

Machine Application Fields:

1. Automobile parts, motorcycle/bicycle tires & tubes.

2. Rubber shoes, soles and heels.

3. Rubber rafts, rubber sheets, rubber tiles, artificial leather.

4. Rubber/EVA sponge soles, EVA products

5. Rubber boots.

6. Rubber nipples, sports balls.

7. Rubber rollers, rice rollers.

8. V-belt and conveyor belts.

9. Rubber cushions.

10. Reclaimed rubberMachine Usage:

This large frame type vulcanizing press is used for producing a special kind of rubber conveyor belts in m. field and it was specially designed for our customer as per his requests.

Normally all our rubber vulcanizing presses are used for suppressing various kinds of rubber products, thermosetting plastic products, and also can be used as common hydraulic presses.

Machine Introduction:

1. Rubber vulcanizing press mainly consists of host machine, hydraulic system, and electronic control system.

2. Fuel tank is installed on the left of host machine, won't be affected by the temperature of host machine.

3. Adopts hydraulic system drive, PLC control, the vulcanizing time, pressure and temperature are all adjustable.

4. Hot platens' temperature is controlled by temperature control system to guarantee the high precision and good quality of final products.

5. PLC control system can accurately realize auto lifting, auto mould open/close, auto air exhausting, auto pressure filling, also with the vulcanizing timing function, vulcanizing alarms function, automatic control & manual control switch function.

6. Mould push-pull device can be configured to improve the efficiency and save labor.Machine Features:

1. Durable frame structure with sufficient raw material applied.

2. Reliable machine quality with superior accessories chosen.

3. Latest machine design.

4. Less maintenance needed.

5. Easy installation.

6. Environment protection.

7. High safety configuration.

8. PLC control system.

9. High efficient and superior vulcanizing performance.

10. Low power consumption & labor saving.Model

Total Pressure (MN)

Daylight (mm)

Working Layer

Piston Stroke (mm)

Main Motor Power (KW)

Overall Dimension (L x W x H) (mm)

XLB-350×350×2

0.25

125

2

250

2.2

1200×580×1200

XLB-400×400×2

0.50

125

2

250

2.2

1400×500×1400

XLB-600×600×2

1.00

125

2

250

2.2

1880×820×1680

XLB-750×850×4

1.60

125

4

500

3

1730×930×2460

XLB-900×900×2

2.5

200

2

400

4

2345×960×1385

XLB-1200×1200×1

3.15

300

1

300

4

2800×1300×2300

XLB-1300×2000×1

5.60

400

1

400

8

2000×1860×2500

XLB-1500×1500×1

8.00

800

1

800

16.5

2200×2200×4300

XLB-1500×2500×1

15.00

400

1

400

11

3000×2500×3300

XLB-2000×3000×1

20.00

800

1

800

26

3600×3000×3800

..

Frame Type Rubber Belt Production Line Making Machine/V Belt Production Line

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products