Professional manufacturer with the design, development and production of rubber and plastic machinery

Share to

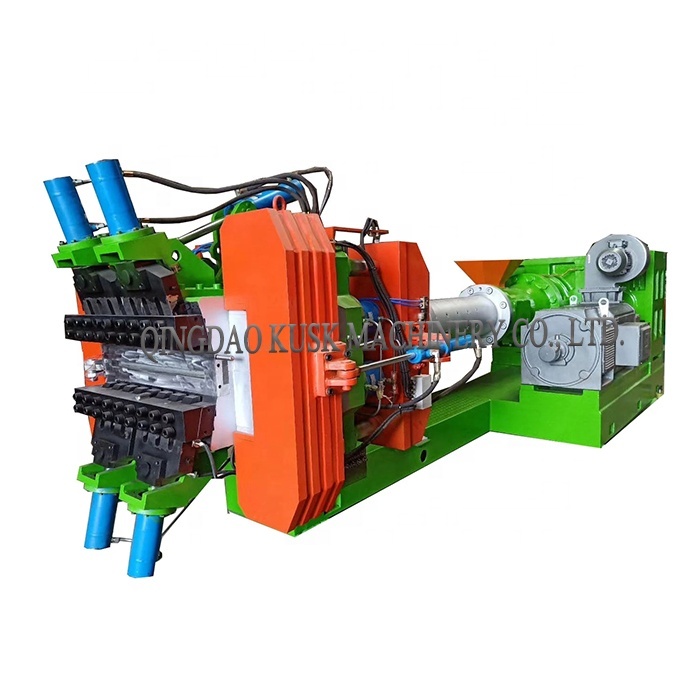

Higher Efficiency Rubber Dispersion Kneader Machine Rubber Mixing Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

higher efficiency rubber dispersion kneader machine / rubber mixing machine

Mixing chamber:

It consists of a "W" shape body and two side boards made of high quality steel plates by means of extrusion forming and welding, which are jacked to take the flow of cooling water or steam. It is plated with hard chrome on its internal walls.

Thermal Resistance:

There is a plug-in thermal resistance in middle section of the bottom of the chamber to be connected to electrical system to inspect and display the temperate.

Rotor:

It is designed to the hollow blades of Banbury type. The hollows are connected with axial hole of rotor shaft used as cooling or heating passage. The top edges of blades and the end faces of ~ rotor shaft are surface welded with cobalt-base hard alloy and grinding, then plating with hard chrome and polishing.

Cooling/heating system:

A common piping system is adopted for either cooling or heating material in mixing operation. Through the system cooling water or steam is fed in three ways to the cavities of the rotors blades, the mixing chamber and the top ram.

Tilting mechanism:

It consists of a rotor with brake, cycloidal gear reducer, TP type worm and worm gear, etc.. It is able to actuate the mixing chamber tilting by 140° around the front rotors.

Dust sealing device:

At the joint between the top of the mixing chamber and the cantilevered arm of the machine frame, the dust sealing assemblies with curved slotted partings are used obtaining an excellent and reliable sealing purpose.

The end face of the rotor is sealed by end contact sealing with nor oil-lubrication and is seals well and is wear-resistant and durable.

Main driving system:

The part is made up with main motor, reducer, connecting gears. It realizes odd-speed rotation of the rotors with running face one other.

Pneumatic control system:

Pneumatic control system is controlled by XG order. The bi-directional air cylinder makes the ram up or down. In case the over load occurs in the mixing chamber, the top ram can be raised automatically or manually if necessary, so as to protect motor from overload.

Electric control system:

Imported PLC device and electric control components which are all imported products or imported technology products are adopted in the electric control system as to raise control reliability.

Model

Item

X(S)N-

1×12~58

X(S)N-

3×32 (6-60)

X(S)N-

10×32

X(S)N-

20×32

X(S)N-

35×30

X(S)N-

55×30

X(S)N-

75×30

X(S)N-

110×30

X(S)N-

150×30

X(S)N-

200×30

Total volume of mixing chamber

L

3

8

25

45

75

125

180

250

325

440

Working volume of mixing chamber

L

1

3

10

20

35

55

75

110

150

200

Driving motor power

Kw

4

5.5

15

30

55

75

110

185

220

280

Tilting motor power

Kw

Manual

0.55

1.1

1.5

2.2

2.2

4

4

5.5

7.5

Tilting angle

.

≤140

135

140

140

140

140

140

140

140

140

Rotational speed of the rotor (front/rear)

r/min

12~58

6-60

32/24.5

32/23.5

32/25

30/24.5

30/24.5

30/24.5

30/24.5

30/24.5

30/24.5

Pressure of compressed air

Mpa

0.5-0.8

0.5-0.8

0.5-0.8

0.5-0.8

0.5-0.8

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

Capacity of compressed air

M³/min

≥0.3

≥0.3

≥0.5

≥0.7

≥0.9

≥1.0

≥1.0

≥1.5

≥2.0

≥2.0

Pressure of cooling water (rubber mixing)

Mpa

0.2-0.4

0.2-0.4

0.2-0.4

0.2-0.4

0.3-0.4

0.3-0.4

0.3-0.4

0.3-0.4

0.3-0.4

0.3-0.4

Pressure of heating steam (plastics mixing)

Mpa

0.5-0.8

0.5-0.8

0.5-0.8

0.5-0.8

0.5-0.8

0.5-0.8

0.5-0.8

0.5-0.8

0.5-0.8

0.5-0.8

Overall dimension

L

mm

1400

1660

2580

2630

3200

3280

3330

3930

4200

4520

W

760

960

1300

1520

1900

1930

2620

3000

3300

3400

H

1914

1750

2280

2550

2950

3070

3340

3660

3900

4215

Weight

Kg

800

2000

3300

4000

6500

7800

10500

16000

19500

22500

..

Higher Efficiency Rubber Dispersion Kneader Machine Rubber Mixing Machine

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products